FFS FILM

FFS Films (Form, Fill, and Seal), available in different formats, are the traditional solution for bagging a large quantity of industrial products, both in granules and powders. As a result of the innovation shared with producers of raw materials and manufacturers of FFS film machines, We have managed to renew the range in terms of quality and performance. It is possible to reach the lowest thicknesses for FFS films for the bagging of polymer compounds, chemicals and fertilizers.

FEATURES:

- Thicknesses from 50mic to 220mic

- Max Diameter up to 1200mm

- Custom print up to 8 colors

- Minimum dimensions 300mm and maximum 1450mm

- Anti-slip varnish; in addition to anti-slip additive

- Protective overprint varnish option

- Also available with reduced thicknesses for consequent reduction of the overall weight of the packaging

BENEFITS:

- High protection of the packed product

- Load stability

- Simple use on all FFS automatic film bagging machines

- Optimal sealing properties

- Efficient high speed filling

- High Sealability

- Extreme versatility

- Excellent mechanical properties

- Hot bagging options

- Microholes for efficient deaeration

Valve and open mouth bags

VALVE BAGS and OPEN MOUTH BAGS available in different formats, are one of the most durable solutions for bagging a large quantity of industrial products, in granules and powders. They are suitable for manual, semi-automatic and automatic use, having a great versatility and predefined dimensions. As a result of the innovation shared with producers of raw materials, we have renewed the range in terms of quality and performance, also adding the NEXTBAG option. Lower thicknesses and thus grams per bag for VALVE bags apt for packing polymer compounds, chemicals and fertilizers.

FEATURES:

- Internal or external valve

- Specific product dimensions tailor made

- High mechanical properties

- Custom printing

- Double bottom for powdery products

BENIFITS:

- High product protection

- Packaging stability

- Simple use, both manual and automatic

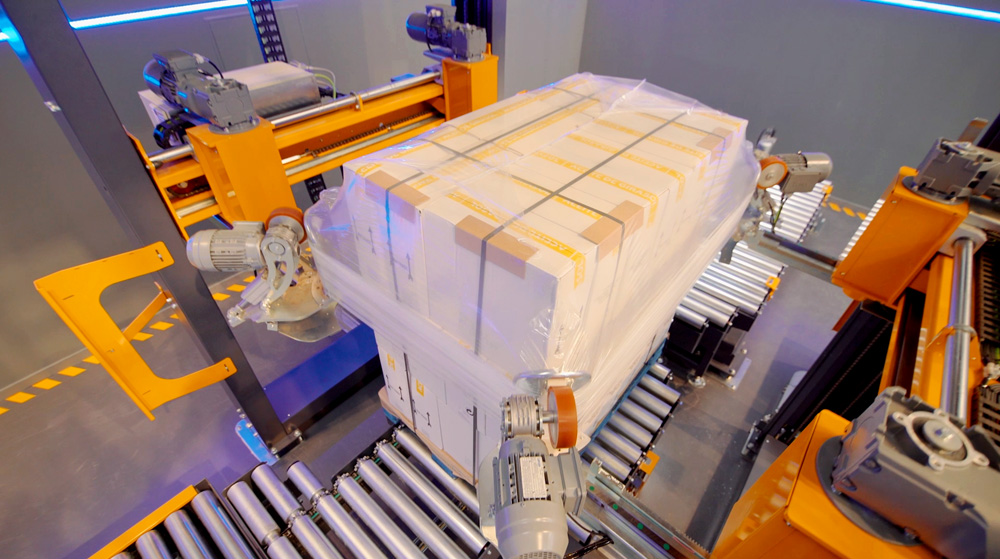

Stretch Hood

Power Stretch Hood is the tubular elastic “hood” packaging that fully wraps the pallet, ensuring protection and stability during transport and handling. Our Power Stretch Hood can reach an extension of 150% with a triple clamping force compared to standard Stretch Hood. Thanks to its high elasticity, with a single format, it can cover various pallet sizes with a material saving of up to 40%.

POWER STRETCH HOOD

FEATURES:

- Lay flat size with gussets from 600mm to 1800mm

- Thickness from 40mic to 180mic

- Maximum integrity of the packaging and stability of the palletized load

- Complete protection from dust and humidity

- High UV protection (both for the film and barrier, up to 24 months)

- Excellent print quality (up to 8 colors)

- Ease of use

- Colored stretch hood – one color or two different colors (outside on and inside another)

BENIFITS:

- Safety during transport

- Material saving per single unit packed

- Reduction of management cost

- No risk of fire and explosion

- Reduced risk of theft and manipulation

- Suitable for packaging thermo-sensitive products